Uyilo lwe-Optical lunoluhlu olubanzi lwezicelo kwintsimi ye-semiconductor. Kumatshini we-photolithography, inkqubo ye-optical inoxanduva lokugxila kwi-beam yokukhanya ekhutshwe ngumthombo wokukhanya kunye neprojekthi kwi-silicon wafer ukubonisa ipateni yesekethe. Ngoko ke, ukuyila kunye nokulungiswa kwamacandelo optical kwi-photolithography system yindlela ebalulekileyo yokuphucula ukusebenza komatshini we-photolithography. Oku kulandelayo ngamanye amacandelo e-optical asetyenziswa kumatshini wokufota:

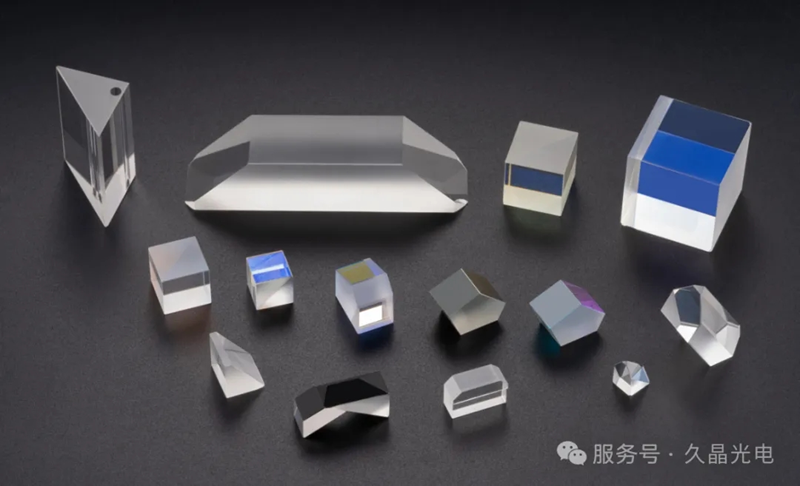

Injongo yoqikelelo

01 Injongo yoqikelelo licandelo eliphambili lokukhanya kumatshini welithography, odla ngokuqulatha uthotho lweelensi ezibandakanya iilensi zeconvex, iilensi eziconcave, kunye neeprism.

02 Umsebenzi wayo kukucutha ipateni yesekethe kwimaski kwaye uyigxininise kwi-wafer eqatywe ngefotoresist.

03 Ukuchaneka kunye nokusebenza kwenjongo yoqikelelo kunempembelelo eqinisekileyo kwisisombululo kunye nomgangatho womfanekiso womatshini welithography.

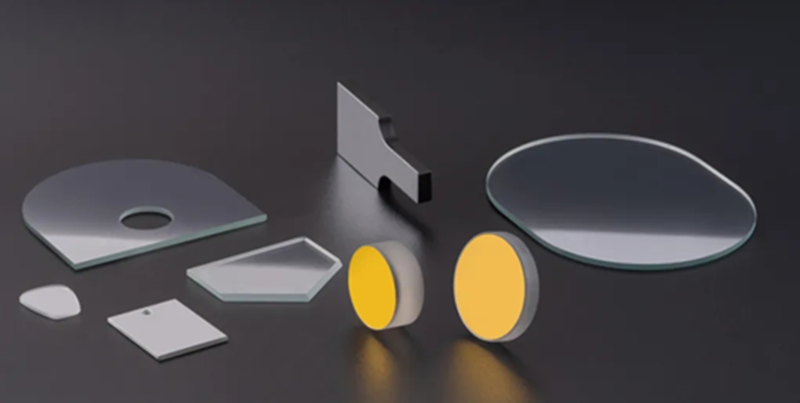

Isipili

01 Izipilizisetyenziselwa ukutshintsha indlela yokukhanya kwaye iqondise kwindawo echanekileyo.

02 Koomatshini be-EUV lithography, izipili zibaluleke kakhulu kuba ukukhanya kwe-EUV kutsalwa lula zizinto, ngoko ke izipili ezinokukhanya okuphezulu kufuneka zisetyenziswe.

I-03 Ukuchaneka komphezulu kunye nokuzinza kombonakalisi kwakhona kunempembelelo enkulu ekusebenzeni komatshini we-lithography.

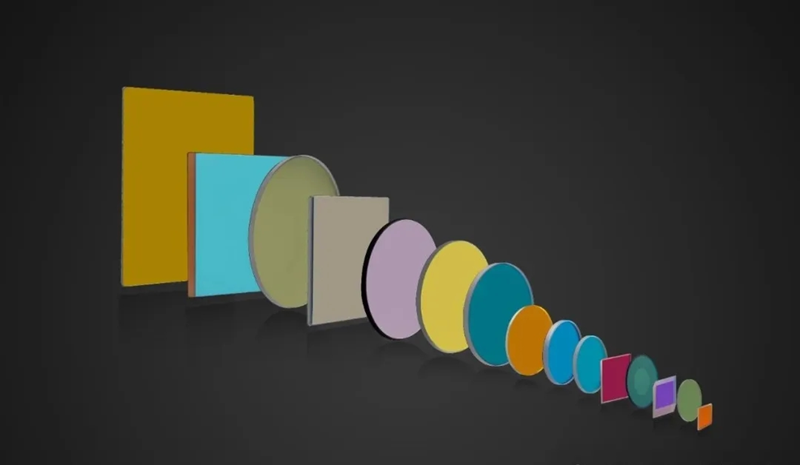

Izihluzi

Iifilitha ze-01 zisetyenziselwa ukususa ubude obungafunekiyo bokukhanya, ukuphucula ukuchaneka kunye nomgangatho wenkqubo ye-photolithography.

02 Ngokukhetha isihluzo esifanelekileyo, kunokuqinisekiswa ukuba kuphela ukukhanya kwe-wavelength ethile kungena kumatshini we-lithography, ngaloo ndlela kuphuculwe ukuchaneka kunye nokuzinza kwenkqubo ye-lithography.

Iiprism kunye namanye amacandelo

Ukongeza, umatshini we-lithography unokusebenzisa amanye amacandelo ancedisayo, njengeeprism, ii-polarizers, njl., ukuhlangabezana neemfuno ezithile ze-lithography. Ukukhethwa, ukuyila kunye nokuveliswa kwezi zixhobo ze-optical kufuneka kulandele ngokungqongqo imigangatho yobugcisa efanelekileyo kunye neemfuno zokuqinisekisa ukuchaneka okuphezulu kunye nokusebenza kakuhle komatshini we-lithography.

Isishwankathelo, ukusetyenziswa kwamacandelo e-optical kwintsimi yoomatshini be-lithography kujolise ekuphuculeni ukusebenza kunye nokuveliswa kwemveliso yemishini ye-lithography, ngaloo ndlela ixhasa ukuphuhliswa kweshishini lokuvelisa i-microelectronics. Ngophuhliso oluqhubekayo lwetekhnoloji ye-lithography, ukulungiswa kunye nokuveliswa kwezinto ezintsha kuya kunika amandla amakhulu okwenziwa kweetshiphusi zesizukulwana esilandelayo.

Ukufumana ulwazi oluthe kratya kunye neengcebiso zeengcali, ndwendwela iwebhusayithi yethu kuhttps://www.jiujonoptics.com/ukufunda ngakumbi malunga neemveliso kunye nezisombululo zethu.

Ixesha lokuposa: Jan-02-2025